When I was building this model, it was an educational experience. I elevated myself as a modeler to the next level by watch youtube channels of other fine modelers, learning new techniques and learning from my mistakes and I made many of them on this build. That said, let's get started.

TO LIGHT OR NOT TO LIGHT...

After seeing so many builds with lighting in them I decided to light this model...that said, I knew I wasn't going to drill 1000 little windows but to just light the main sections (Warp Engines, Nav Deflector, Impulse Engines, Nav Lights). At one of the many electronic shops in Toronto, they sell LEDs for cheap (sometimes 20 cents each!) and LED tape in many colours at Active Surplus as well as Warm Wight Double density LEDs tape at Lee Valley Tools. That kind of accessibility allowed me to get creative with this model vs. ordering online (which I do a lot of nowadays). When I built my previous USS Enterprise-D models, the warp nacelles were extremely spotty as they were solely lit with 'grain of wheat' bulbs and the blue warp glow always had a greenish hue. Here is y first test:

The domes need to be frosted - what I would do now is use steel wool. At the time I used 400 Grit Wet Sandpaper.

In both the schematics for the Ent-D and from what you can see on the show, there are 2 sources of light in each Bussard. What I did was tint 2 LEDs Tamiya Orange and on the tips (later on) red. the light block I used 'hammered paint' to hopefully disperse the light.

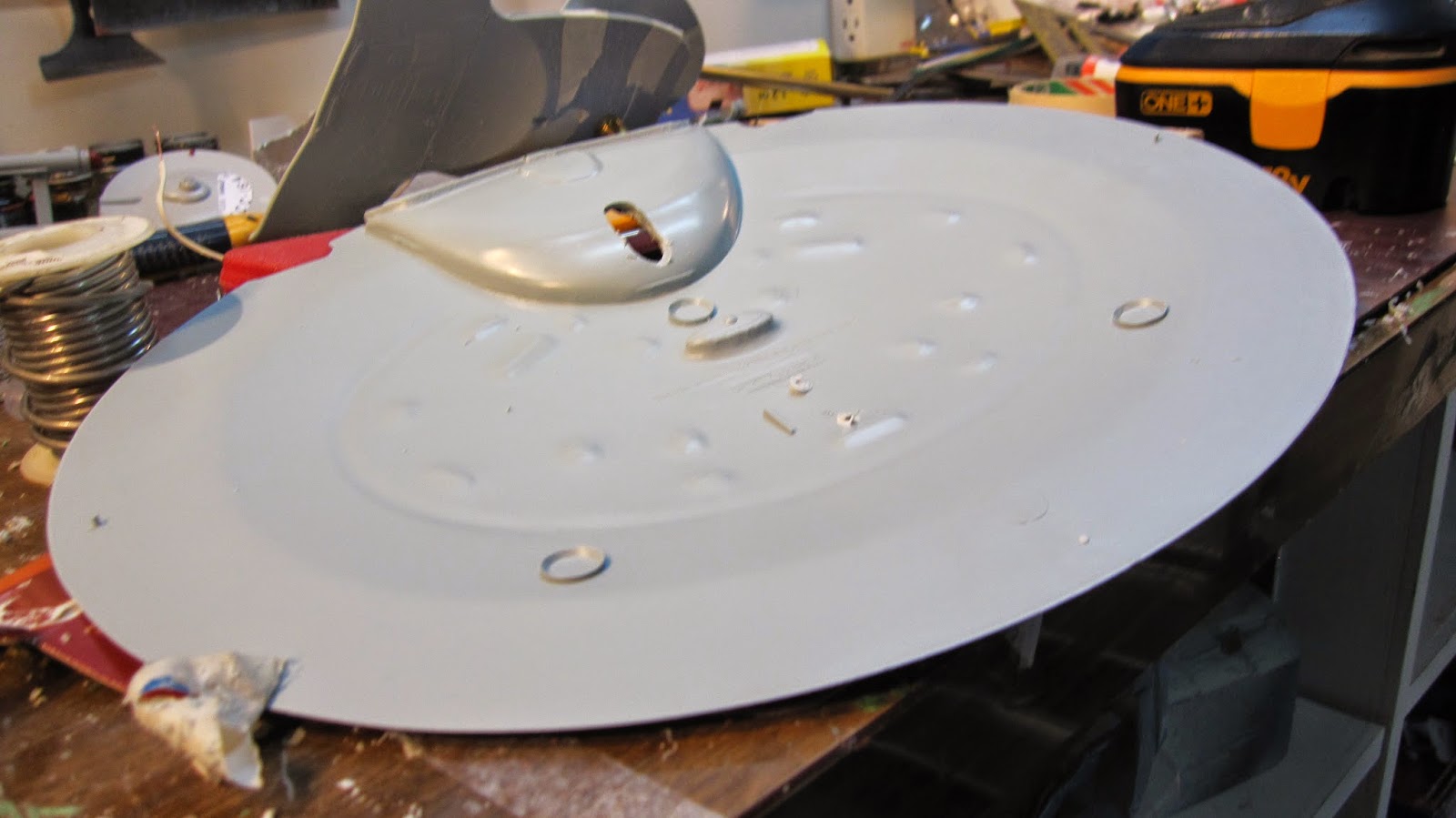

STRUCTURAL INTEGRITY SYSTEM

Fancy way of saying armature. I toyed around having multiple mount points at one point but the logical choice is on the lowest deck. The armature is a solid (and thick) brass lamp rod. I thought about using elements or even making the saucer detachable - too advanced for my skill level at the time. I bent the rod using a table vise and had the fore thought to make 2 of them (clear Ent-D down the road...)

This model ain't separating.

If this was the clear model, this would be perfect!

And for the nacelle section...

In future, I wouldn't have glued it all together at once. This will come back to haunt me...

A note, the base here is a left over piece of 2x8 used in a recent construct project - it will become the final base down the road. I also found a scrap piece I currently use as a temporary base.

'THEY'RE CARVING US UP LIKE A ROAST' - Riker, 'Q Who'

My biggest concern was building the nacelles and having them warp - a warp ship shouldn't warp! What I did was take a note out of how the studio model was built. The lower engine hull has the nacelle pylons molded to it in one piece and the weakest point is where the curve begins. So, I cut that off.

Having built this model, this was a smart decision! It also makes lighting that much easier. I can easily attach the nacelles at the correct angle and then add the lower hull. If it bends, the nacelles don't and having recently seen this model finished, The nacelles are as straight as when I built it.

Now, that wasn't the only thing I cut off, I cut off the section between the phaser bank and the Nav Deflector. The reason I cut it off was for this reason: the deflector is a poor fit in the model and I wanted a way to adjust it when the top and bottom pieces are together by pushing from behind. Again I took the idea from the 6' model. The only thing I would do differently would be making my incision line down the middle of the phaser bank and order the brass etched phaser banks from Don's Light and Magic.

Next step, remove the raised aztec lines. The 6' model was SMOOTH! The 4' model was SMOOTH too except for raised aztec's by primer not ridges! Some people go head over heals when the TOS Enterprise is misrepresented, especially as the 1/350 has scribed grid lines. Well, the TNG Enterprise was SMOOTH, except for it's lightly scribed grid lines. So, let's sand down this unnecessary detail...

The 'decal' is a modified one...it's the Serbian 2-headed eagle instead of the chevron and elliptical shield. I've seen many builds of Star Trek models follow cultural heroes or even all female crews, why not Serbian?? or Canadian, my country - and I've seen a "Canadian Star Ship" build before too. I digress. The theme of this model is Serbian as my friend is Serbian. Also why it's called 'Tesla' not to mention the godfather of electricity should be honoured in the fictional 24th C. The series Enterprise touched on this with still having naval ships named 'HMS'... I digress.

Some of these following pics are a bit blurry, my bad...Removing inaccurate detail.

Stay tuned for the next retro update and the update on the 'Space Seed' diorama.

Cheers!! Happy modelling!

ADDENDUM - THE ARMATURE

When I built this model last summer, I had two of the same lamp parts, which I bent on a vise at the same time. Admittedly, I never measured with a tape measure or ruler but transferred the marks from the hull. The better of the two I used in this build, the 'Tesla'. This is the 2nd armature compared to my clear Enterprise D...

The yellow tape represents the area on both sections which needs to be bored out, although not right to the edge.

This is the alignment on the neck. There is a subtle cure to the spine of the 'D' but it is generally bent 45 degrees from the plane of the saucer.

I bent the metal rod at the following points from the thread outwards:

1 5/16" (33.3 mm)

1 3/16" (30.2 mm)

9 1/2" (241.3 mm)

Each bend was bent at 45 degrees.

Here is the layout of this metal part:

Even if the degrees are a bit off from 45, the most important part is having a proper right angle so the saucer will be parallel to the base.

To attach the armature to the rod from the base, I use a coupler.

Locating the hole to cut in the lower engineering hull was sort of tricky. When I decided to make the downward bend, I knew I wanted the hole to be somewhere between the phaser strip, and not to interfere with the decal. When I was locating it, I printed off/photocopied the pennant decal as a reference. I held the whole model (engineering hull halves, battle head and only 1 half of the neck and lower saucer) with masking tape to find exactly where the hole would go. I have to admit, I was of by fractions of an inch (or a few millimetres) and had to use additional bracing of styrene.

Another option would be to use bits of sprue. I save most of my sprue from my models since the 90's.

For the armature for the nacelle pylon, I used a flat piece of aluminium stock, available from Lowes. Hobby stores may sell either aluminium or brass, I used the lighter (and cheaper) option.

The exact dimensions of this piece I no longer have. I cut it down with a hack saw and drilled out the hole on a drill press. The same could be accomplished by using a drill and stepping up the sizes from a smaller opening to a larger opening. What I did to secure it to the main armature after locating the correct position (by eye) and a small level was to sandwich it between washers and lamp nuts and using hot glue to lock it down.

Finally, the last thing to mention is the wiring. I had a main cable run through the hollow tube to the saucer. The remaining wires were re-routed back through additional holes in the neck of the 'Tesla'. I would do this much differently now.

Happy Modelling!!

No comments:

Post a Comment